Enerac 3000E SEM

Documented Quality Assured Performance:

The ENERAC Model 3000E is the most advanced and accurate electrochemical emissions analyzer ever produced. With its range of automatic QA/QC capabilities, the Enerac 3000E provides accurate, documented, defensible data for compliance monitoring purposes, e.g. NSR, Title V Periodic Monitoring, CAM Plan Development, Emission Trading, PAL, Audits, etc.

Enerac 3000E-3IR SEM uses state-of-the-art infrared technology to accurately measure CO, CO2, & hydrocarbons.

Measurement of Hydrocarbons by infrared technology

The new Enerac and 3000E SEM-HC includes all the features of our most advanced emissions analyzer and in addition measures hydrocarbon concentrations using the latest state-of-the-art infrared technology.

The new hydrocarbons measurement capability replaces the previous combustibles measurement that used catalytic technology and is offered as an add-on option for customers.

The hydrocarbon measurement features:

- Meets EPA’s Reference Method 25B “Determination of Total Gaseous Organic Concentration Using a Nondipersive Infared Analyzer”

- Measures Hydrocarbons as propane using the latest state of the art pulsed infrared LED emitter and dual lead selenide detector technology

- Exceptional stability and accuracy at very low power consumption (less than 3 watts)

- Less than 1 minute warm up time

Specifications

Measurement gas: Hydrocarbons (as propane)

Range: 0-20,000 PPM (0-2%) by volume

Operating Principle: Non dispersive infrared

Accuracy: +/-5% of reading or 0.01% volume (whichever is greater)

Repeatability: +/-2% of reaing or 0.01% volume

Maximum zero drift (per year): +/- 0.02% volume

Response Time: <10 sec

Warm up time (@22 deg. C): 60 seconds

Operating Temperature range: -10 to 40 deg. C

Operating humidity: 5-95% non condensing

The Enerac 3000E series:

- Meets All the Performance Specifications of EPA’s Test Method for the Determination of Nitric Oxide, Nitrogen Dioxide, and NOx Emissions from Stationary Combustion Sources by Electrochemical Analyzer, (Performance Specifications are Equivalent to Method 7E)

- Meets All the Performance Specifications of EPA’s Method 2, Determination of Stack Gas Velocity and Volumetric Flow Rate (Type S Pitot Tube), 40 CFR 60 Appendix A.

- Important QA/QC Capabilities Are Always Available to Insure Accurate, Documented, Defensible Data. They Include:

- Automatic Calibration Certification Protocol Tests and Documents Proper Sensor and Interference Rejection Filter Performance before each test

- Replaceable Interference Rejection Filters to Insure Specificity

- Dual Range Sensors to Adjust a Sensor’s Sensitivity Range to Accommodate Different Measurement Ranges (NO: 5 – 5000 PPM)

- Auto Temperature Control System for the NO Sensor

- Integrated Capabilities Provide Mass Emissions Data

- Advanced Communications and Data Management:

- Two Way Communications Bring Factory Assistance to Your Site

- Automatically Calculates lb/mmbtu, gr/Bk-hp-hr; O2 reference adjustment, lbs/hr., tons/year for (CO2)

- Enercom for Windows Software Captures, Stores and Graphs Data in a Variety of Common Formats for Direct Use by Major PC Programs

- Enerac’s Comprehensive Field and Factory Training

Enhanced Integrated Sample Conditioning System

This is a unique battery operated permeation dryer conditioning system. It has been shown to remove excess water vapor without any loss to the nitrogen dioxide and sulfur dioxide components of the stack gases.

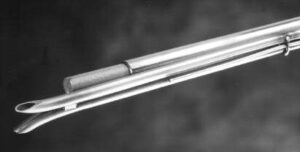

Electrochemical SEMTM Sensors

These are the most advanced electrochemical sensors specifically designed for emissions measurements. SEM sensors are available for the measurement of nitric oxide, nitrogen dioxide, carbon monoxide and sulfur dioxide components of the stack gases.