|

The Unique Patented* Pressure |

|

|

|

Coverslips just like you would,

if you had to...! |

H/I Robot CoverSlipping Machine RCM3660

|

The Unique Patented* Pressure |

|

|

|

Coverslips just like you would,

if you had to...! |

| BENEFITS | SYSTEM & LAYOUT |

| IMPROVED QUALITY CONTROL AND PRODUCTIVITY | Only the HACKER-MEISEI

RCM emulates the ideal method of coverslipping. It repeats this patented technique consistently and continuously. Flexing action insures delivery of just one coverslip at a time. |

| OPTIMUM SEAL

AND COVERAGE FOR ALL HISTOLOGY AND CYTOLOGY SLIDES |

Mountant dispersement options are virtually unlimited. |

| MAXIMUM CONTROL AND RELIABILITY | Magic Fingers systematically and individually address each slide, moving it from the holding basket, through coverslipping and into one of three individually removable storage racks. |

| EASY ACCESS TO LOAD AND UNLOAD SLIDES AND CONSUMABLES | User friendly layout. Counter on control panel keeps an accurate count of slides coverslipped, so reloading consumables and PM time are no longer a guessing game. |

| NO FUSS ACCESS TO ALL INTERNAL COMPONENTS | Easy access panels are removed in seconds for access to internal boards and mechanics. |

| NO NONSENSE

PUSH BUTTON OPERATION. OPERATOR CAN DETERMINE SYSTEM STATUS AT A

GLANCE INDICATORS PROMPT TECHNICIANS TO RE-LOAD AND/OR ADJUST EXACTLY AS REQUIRED |

Control panel monitors each step of the coverslipping operation and indicates current status. Alarm signals are audio/visual informing operator when consumables are needed, and coverslipping has been completed. The system will stop and call for the operator should it encounter broken slides, coverslips or any other situation which requires operator intervention. |

| COMPATIBILITY

WITH OTHER SYSTEMS, AUTOMATED AND MANUAL |

Slide baskets

interface with most automated staining systems. Can also be used for hand staining. |

| MORE TIME FOR OTHER LAB FUNCTIONS | The RCM3660 is a fully enclosed, walk-away system. It allows technicians to attend to other tasks while coverslipping takes place, as well as contributing to a cleaner, healthier laboratory. |

| CLEANER, HEALTHIER ENVIRONMENT | Operator interface occurs only for loading and unloading slides and consumables. |

| COST REDUCTION AND CONTAINMENT | The RCM3660 coverslips up to 360 slides per hour. Test studies show, that the RCM virtually pays for itself over three years in laboratories with moderate volume. |

| Specifications - RCM3660 Robot Coverslipping Machine | ||

| SYSTEM | - Control - Environment |

microprocessor temperature 10 - 40° C humidity 30 - 90% RH |

| COVERSLIPPING | - Time/slide - Method |

12 seconds per slide pressure bending |

| GLASS SLIDE | - dimensions - Capacity - Holding Method (before coverslipping) - Storage (after coverslipping) |

25 x 76 mm (1 x 3 in.) -

polished edge - 1.0 mm thickness up to 60 standard basket set in enclosed holding trough with xylene or sylene substitute stored in storage rack |

| COVERSLIP | - Width - Lengths - Thickness - Capacity |

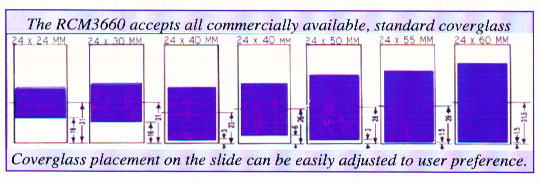

22mm, and 24 mm (preferred) 40mm, 50mm, 55mm, 60mm 0.13mm up to 130 |

| MOUNTANT | - Method - Type - Viscosity - Dispensing Volume - Capacity |

line drop - variable length

selection one point drop commercial, compatible w/ clearant 80 to 800 cp 0.15 - 1,2 seconds variable 150cc max |

| FUME CONTROL | - Standard - Optional |

built in exhaust fan activated carbon filter |

| POWER | - Standard - Optional |

AC117 + 17V 50/60 Hz 300VA 200V 50/60 Hz 300VA |

| ALARM | - Error Message Indication for: |

coverglass pick up slide pick up dispenser position slide storage |

| INDICATOR | for reloading consumables & maintenance | shows quantity of slides coverslipped |

| DIMENSIONS | Bench space | 20 x 21 x 27 in width - 19 in, + 8 in for ducting depth - 21 in, + 7 in for carbon filter height - 27in, + 14 in to open cover |

| WEIGHT | 143 lb. / 65 kg | |

Giangarlo

Scientific | Analytical | Environmental | Life Science | Process | Safety | Wastewater | Service | Contact

Us